Injection molding is a pivotal manufacturing process widely used across industries for producing plastic components with precision and efficiency. Choosing the right injection molding supplier is crucial for ensuring the quality, cost-effectiveness, and timely delivery of your molded products. Here's a guide to help you navigate through the selection process and find the perfect injection molding partner.

1. Industry Expertise

Start by evaluating the injection molding supplier’s industry expertise. Look for a supplier with experience in manufacturing components similar to your requirements. Specialized knowledge in your industry ensures that the supplier understands the unique challenges and specifications associated with your products, leading to better outcomes.

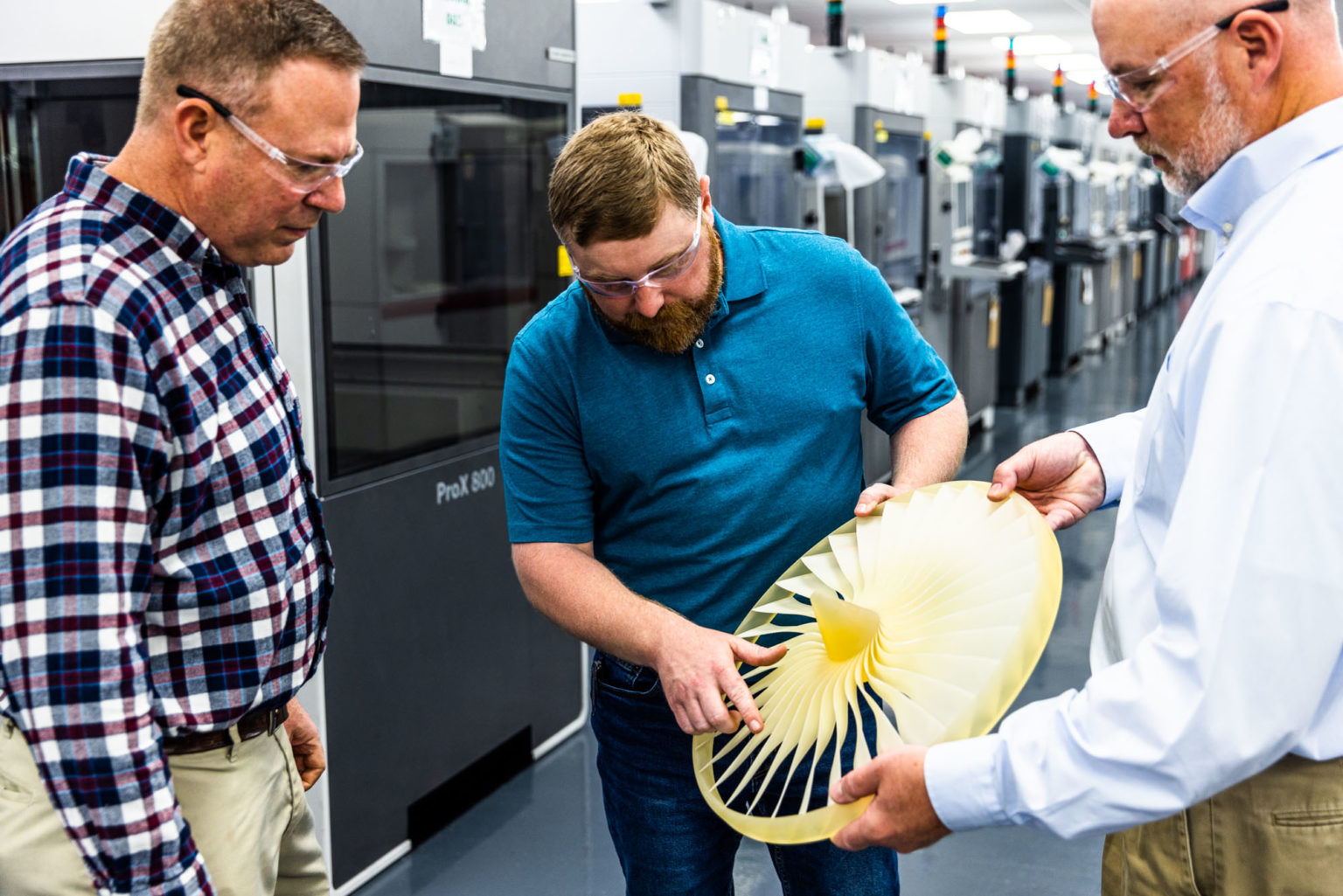

2. Technological Capabilities

Assess the technological capabilities of potential injection molding suppliers. State-of-the-art machinery, advanced molding techniques, and a commitment to technological innovation contribute to higher precision and efficiency. Inquire about the supplier's equipment, software, and quality control measures to ensure they can meet your specific molding requirements.

3. Quality Management Systems

Quality is paramount in injection molding, and reliable suppliers adhere to stringent quality management systems. Check if the supplier has certifications such as ISO 9001, which signifies a commitment to maintaining high-quality standards. A robust quality management system ensures consistency in product quality and compliance with industry regulations.

4. Material Expertise

Different plastic materials have distinct properties, and the right injection molding supplier should have expertise in handling a variety of materials. Whether your project requires common thermoplastics or specialized engineering plastics, a knowledgeable supplier can guide you in selecting the most suitable material for your components.

5. Production Capacity and Scalability

Consider the production capacity and scalability of the injection molding supplier. A reliable partner should have the capacity to handle your current project's volume while also accommodating potential future expansions. Scalability ensures that the supplier can grow with your business and maintain consistent production levels.

Conclusion

Selecting the right injection molding supplier involves a comprehensive evaluation of their expertise, technological capabilities, quality management systems, material expertise, production capacity, customization options, cost-effectiveness, communication, reputation, and environmental considerations. By prioritizing these factors, you can establish a reliable and collaborative partnership that ensures the success of your injection molding projects.